As the global transition toward sustainable urban logistics accelerates, the performance expectations of e-cargo bikes and light electric vehicles (LEVs) continue to rise. Operators are no longer satisfied with large batteries alone—they require vehicles that deliver consistent, predictable, and long-lasting efficiency in demanding real-world environments.

While battery capacity initially dominated industry discussions on range, the focus is now shifting toward a far more influential factor:

the efficiency and architecture of the drivetrain—especially the Rear Axle Motor system.

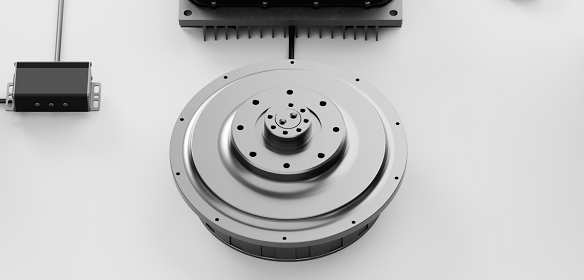

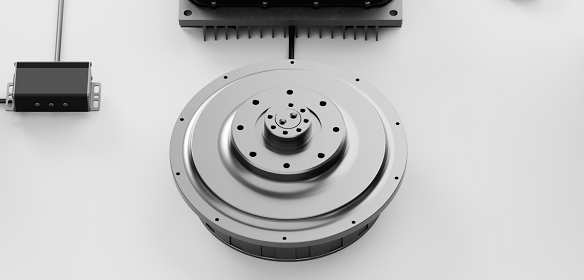

Rear Axle Motor technology has quickly emerged as a key enabler of stable long-range performance. Companies such as LUXMEA, known for engineering fleet-oriented, reliability-focused mobility systems, have embraced this architecture to support next-generation commercial electric mobility.

This article provides a technical and industry-focused analysis of why Rear Axle Motors are becoming central to high-efficiency LEV platforms.

1. Redefining Efficiency Through Drivetrain Architecture

Traditional hub motors and mid-drive motors both have strengths, but they also introduce energy losses—either through complex mechanical pathways or increased gear friction. Rear Axle Motors approach the problem differently.

Direct-Drive Power Path

By delivering torque directly through the rear axle, the system minimizes:

Mechanical transmission losses

Chain-related inefficiencies

Gear friction present in mid-drive designs

This direct architecture ensures higher energy conversion efficiency, meaning more usable power per watt-hour of battery capacity and significantly improved real-world range.

2. Optimized Low-Speed Torque for Commercial Loads

Commercial LEVs face operational conditions that differ dramatically from those of consumer e-bikes:

Frequent start–stop cycles

Heavy payload demands

Urban gradients and uneven surfaces

Continuous low-speed operation

Rear Axle Motors excel in these scenarios due to their efficient low-speed torque delivery.

High Torque with Lower Current Draw

Because power is applied where it is needed most—at the rear wheel—Rear Axle Motors:

Reduce peak current requirements during acceleration

Lower heat generation under load

Maintain high efficiency across varying terrain

This explains why logistics-oriented manufacturers, including LUXMEA, prioritize Rear Axle Motor systems for long-range, high-duty-use vehicles.

3. Durability and Reduced Total Cost of Ownership (TCO)

For fleet operators, the long-term cost and operational uptime of an LEV are as important as performance.

Rear Axle Motors deliver measurable advantages in durability:

Less Mechanical Stress

Mid-drive systems amplify chain tension, accelerating the wear of:

Chains

Sprockets

Cassettes

Rear Axle Motors avoid these issues entirely, leading to:

Longer component lifespan

Fewer workshop interventions

Lower overall maintenance costs

Enhanced Environmental Protection

With a compact and sealed motor housing, Rear Axle systems offer:

Superior water and dust resistance

Stable performance across weather conditions

Consistent functionality over thousands of operating hours

For fleet-oriented brands like LUXMEA, these durability characteristics directly support the goal of maximizing vehicle uptime and reducing lifetime service costs.

4. Predictable Energy Consumption: The Real Advantage

While absolute range numbers are important, predictability often matters more—especially for logistics operations where route planning and shift scheduling depend on reliable energy patterns.

Rear Axle Motors maintain a stable efficiency curve across:

Consistent Wh/km Performance

Operators benefit from:

More accurate route planning

Reduced mid-shift battery swapping

Linear and predictable State-of-Charge (SOC) behavior

Fewer operational disruptions

This consistency is one of the main reasons Rear Axle architecture is becoming a preferred choice in fleet-grade LEV applications.

5. Rear Axle Motor + Intelligent BMS: A High-Efficiency Ecosystem

The full potential of Rear Axle Motors is unlocked when paired with advanced battery management systems.

Synergy of Motor and Energy Intelligence

When combined with a smart BMS—such as those implemented in LUXMEA's fleet-designed battery platforms—the system achieves:

Optimized torque-to-power delivery

Improved thermal regulation

Reduced current stress at low temperatures

More accurate SOC/SOH predictions

Smoother and safer power distribution

This integrated approach can lead to:

10–25% increases in real-world range

Reduced battery degradation

More stable performance throughout the battery lifecycle

Rear Axle Motors, when supported by intelligent power management, represent a major step toward truly energy-efficient commercial mobility.

6. Industry Adoption: Why the Shift Is Accelerating

Across Europe and Asia, leading cargo-bike and LEV manufacturers are moving toward Rear Axle architecture for upcoming platforms. The reasons reflect broader industry needs:

Higher torque at low speeds

Smoother starts with heavy payloads

Compatibility with automatic shifting systems

Reduced chain and gear wear

Better integration with IoT fleet management tools

As cities adopt stricter emissions regulations and demand reliable last-mile delivery solutions, the role of efficient drivetrains will only grow.

Rear Axle Motor systems are well-positioned to meet these evolving demands—and companies like LUXMEA are strategically incorporating this architecture into their long-range commercial vehicle ecosystem.

Conclusion

Long-range performance is no longer solely defined by increasing battery capacity.

The industry is entering an era where drivetrain architecture and system-level efficiency determine true operational range.

Rear Axle Motor systems deliver:

Higher energy efficiency

Superior low-speed torque

Lower mechanical wear

More predictable energy consumption

Reduced long-term operating costs

For forward-thinking manufacturers and fleet operators, Rear Axle technology is rapidly becoming a foundational element of next-generation electric mobility.

By integrating this architecture into its product ecosystem, LUXMEA continues to advance high-efficiency, fleet-ready mobility solutions designed for the future of urban logistics.

FAQ

1: Why are rear axle motors more efficient?

A: They deliver power directly to the rear wheel, reducing mechanical losses and improving overall energy efficiency.

2: Why are rear axle motors ideal for cargo and fleet use?

A: They provide strong low-speed torque, handle heavy loads well, and reduce drivetrain wear—making them more reliable for daily commercial operations.