For decades, success in urban mobility was defined by performance.

How fast could it go? How much could it carry? How far could it travel on a single charge?

But as electric fleets — from commercial cargo e-bikes to last-mile delivery vehicles — become the backbone of modern cities, the conversation is changing.

Today's most sophisticated fleet operators are no longer asking about top speed.

They are asking a more strategic question:

How long can this vehicle stay out of the workshop?

The rise of low-maintenance design in urban mobility is not a passing trend. It is a direct response to the economic realities of high-frequency city logistics. In an environment where uptime determines profitability, serviceability has become the most important performance metric of all.

We are entering what can be called the Availability Era.

From Performance to Availability

In early electric mobility, marketing focused on battery range and payload capacity. While those specifications still matter, professional fleet operators now evaluate vehicles differently. They focus on:

A vehicle that spends fewer days in service generates more revenue. A platform engineered for durability reduces unpredictable operating costs.

In commercial fleet management, uptime is revenue.

The End of Reactive Maintenance

The traditional consumer maintenance model is reactive: something fails, the rider notices, and repairs follow.

In urban fleet operations, that model does not scale.

Modern low-maintenance vehicle design shifts from reactive repair to proactive system management. This shift is powered by structured, automotive-inspired system architecture.

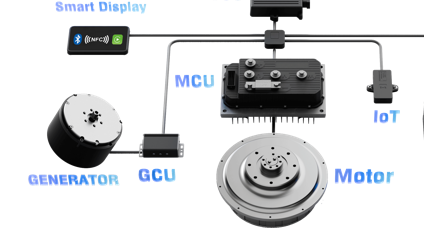

Instead of operating as closed "black boxes," today's advanced commercial electric vehicles are built with diagnostic transparency in mind. Standardized communication protocols and structured electronic frameworks allow the system to continuously monitor its own health.

Small irregularities — such as slight thermal deviations or electrical imbalance — can be identified before they escalate into system failure.

The result?

A scheduled 20-minute service intervention instead of a multi-day breakdown investigation.

Predictability replaces uncertainty.

Architectural Isolation: Preventing System Contagion

One of the biggest cost drivers in early electric fleets was what engineers informally call "fault contagion."

A minor issue in a display, GPS module, or connectivity unit could sometimes trigger a full system shutdown. A non-critical glitch could immobilize the entire vehicle.

Low-maintenance design addresses this through architectural isolation.

Modern commercial platforms increasingly separate safety-critical systems (motor control, braking, battery management) from intelligent modules (connectivity, user interface, smart access control). By isolating these networks, non-essential software errors cannot interfere with core vehicle operation.

If a connectivity module crashes, the motor continues to function.

If a fleet app update fails, the powertrain remains stable.

This separation dramatically reduces total vehicle shutdown events and keeps vehicles operational even when peripheral systems need updates.

In high-density urban logistics, this difference is measurable in uptime percentage points.

Hardware Hardening: Engineering for Harsh Urban Reality

Urban mobility is not gentle. Vehicles endure:

Low-maintenance electric cargo bike design increasingly borrows from automotive durability standards.

Key improvements include:

Sealed, high-protection electrical connectors

Reinforced cable routing

Water-resistant battery enclosures

Corrosion-resistant structural materials

Shock-absorbing component mounting

By protecting the vehicle's "nervous system" from environmental stress, operators significantly reduce the most common cause of electrical failures: moisture and corrosion.

Even motor control systems have evolved. Advanced drive control reduces mechanical vibration and component strain. Less vibration means fewer loose fasteners, fewer structural fatigue points, and longer inspection intervals.

Durability begins at the design stage.

Digital Access: Eliminating Small but Costly Failures

Maintenance challenges are not limited to motors and batteries. Small mechanical components often generate disproportionate operational headaches.

Physical keys are a classic example in fleet environments. They break, get lost, jam with dirt, or require frequent cylinder replacements.

Low-maintenance urban vehicle design increasingly integrates digital access systems, such as NFC-based locking or cloud-managed permissions. These solid-state systems eliminate mechanical wear components entirely.

Access rights can be assigned or revoked remotely.

There are no keys to replace, no cylinders to lubricate, and no physical parts to fail.

While seemingly minor, these design choices significantly reduce service interruptions across large fleets.

TCO: The Real Financial Equation

For professional operators, the true cost of a vehicle extends far beyond purchase price.

Total Cost of Ownership over 24 to 36 months includes:

A low-maintenance vehicle may require higher upfront investment in higher-grade controllers, reinforced components, and structured electronic architecture. However, when service intervals are extended and failure rates reduced, the financial advantage becomes clear.

Reduced Standard Labor Time (SLT) for repairs

Fewer emergency interventions

Longer operational lifespan

In commercial fleet economics, stability outperforms raw performance.

Sustainability Through Longevity

Sustainability in urban mobility is often framed in terms of emissions. But durability is equally important.

Longer vehicle lifecycles mean:

Fewer component replacements

Reduced material waste

Lower production frequency

Smaller environmental footprint over time

Low-maintenance design aligns economic efficiency with environmental responsibility.

In European markets where ESG standards increasingly influence procurement decisions, durability is not just operationally smart — it is strategically necessary.

The Future of Urban Fleet Design

Urban logistics is becoming more professionalized, more data-driven, and more competitive.

The next generation of electric cargo bikes and light commercial EVs will not be judged solely by speed or battery size. They will be evaluated by:

The industry is moving beyond the repair shop mindset.

The most advanced feature a commercial urban vehicle can offer is not higher acceleration or marginally longer range. It is the ability to keep moving — consistently, reliably, and predictably — under real-world stress.

In the Availability Era, low-maintenance design is no longer an engineering preference.

It is a strategic advantage.